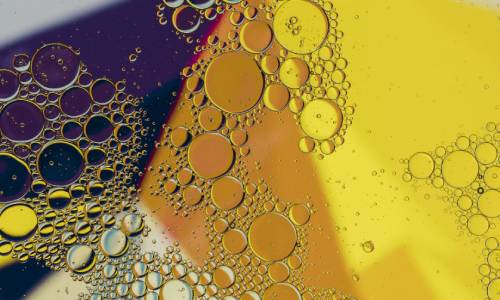

Emulsion polymerisation

Emulsion Polymerisation: Providing Versatile Polyvinyl Acetate Homopolymer (PVA) Emulsions

Emulsion polymerisation is a highly effective method for producing polymers, and among the diverse range of emulsions available, Polyvinyl Acetate (PVAc) homopolymer emulsions stand out as a remarkable product offered by Kaiser Industries Limited. PVAc emulsions are derived from the emulsion polymerisation of vinyl acetate monomer (VAM) and are known for their exceptional adhesion properties, making them a top choice in various industrial and consumer applications.

Unrivaled Adhesion in Versatile Applications

Kaiser Industries’ PVAc homopolymer emulsions are renowned for their exceptional adhesion capabilities, making them an ideal choice for a multitude of applications. The versatility of these emulsions extends from traditional uses in wood glues and school glues to a wide array of industrial and consumer end-use applications.

Unrivaled Adhesion in Versatile Applications

Kaiser Industries’ PVAc homopolymer emulsions are renowned for their exceptional adhesion capabilities, making them an ideal choice for a multitude of applications. The versatility of these emulsions extends from traditional uses in wood glues and school glues to a wide array of industrial and consumer end-use applications.

High-Performance Water-Based Adhesives

In the realm of water-based adhesives, Kaiser’s PVAc emulsions have proven to be a preferred choice. These adhesives exhibit robust bonding properties, making them ideal for bonding various materials, including wood, paper, cardboard, and fabrics. With excellent tackiness and cohesive strength, PVAc emulsions ensure long-lasting and reliable adhesion.

Dependable Carpet Backings

Carpet backings demand a stable and durable bond between the carpet fibers and backing material. Kaiser’s PVAc homopolymer emulsions deliver exceptional bonding performance in carpet manufacturing processes. These emulsions create strong, flexible, and moisture-resistant carpet backings, enhancing the overall quality and durability of the finished product.

Dependable Carpet Backings

Carpet backings demand a stable and durable bond between the carpet fibers and backing material. Kaiser’s PVAc homopolymer emulsions deliver exceptional bonding performance in carpet manufacturing processes. These emulsions create strong, flexible, and moisture-resistant carpet backings, enhancing the overall quality and durability of the finished product.

Superior Paper and Paperboard Coatings

The paper and paperboard industry rely on high-quality coatings for surface protection and improved printability. Kaiser Industries’ PVAc emulsions offer a perfect solution with their excellent film-forming properties. These emulsions create smooth, glossy, and water-resistant coatings, enhancing the aesthetics and functional characteristics of paper and paperboard products.

Innovative Building and Construction Products

In the dynamic world of building and construction, PVAc homopolymer emulsions play a pivotal role. They are employed in various applications, such as tile adhesives, sealants, and cement modifiers, to enhance the overall performance and longevity of construction materials. With their strong adhesion and compatibility with different substrates, these emulsions ensure reliable and enduring bonds in diverse construction projects.

Innovative Building and Construction Products

In the dynamic world of building and construction, PVAc homopolymer emulsions play a pivotal role. They are employed in various applications, such as tile adhesives, sealants, and cement modifiers, to enhance the overall performance and longevity of construction materials. With their strong adhesion and compatibility with different substrates, these emulsions ensure reliable and enduring bonds in diverse construction projects.

Kaiser Industries' Unparalleled Support

Kaiser Industries Limited is not only renowned for its top-quality PVAc homopolymer emulsions but also for its unmatched customer support. Leveraging decades of experience, the company offers tailored emulsions and expert guidance to meet the specific needs of customers. The dedicated team of polymer chemists collaborates closely with clients, assisting them in evaluating emulsifier types, optimal levels, and ratios to achieve the desired performance in their applications.